Rotational Molding Service

Custom rotational molding services for plastic prototypes and on-demand production parts. Get a free rotational molding quotation and design feedback within hours.

- No minimum order quantities

- Rapid Tooling Production as fast as 2 weeks

- ISO 9001:2015 certificated

- 24/7 engineering support

7sets

Molding Machines

5types

Surface Finishes

1pcs

MOQ

0.5mm

Tolerance

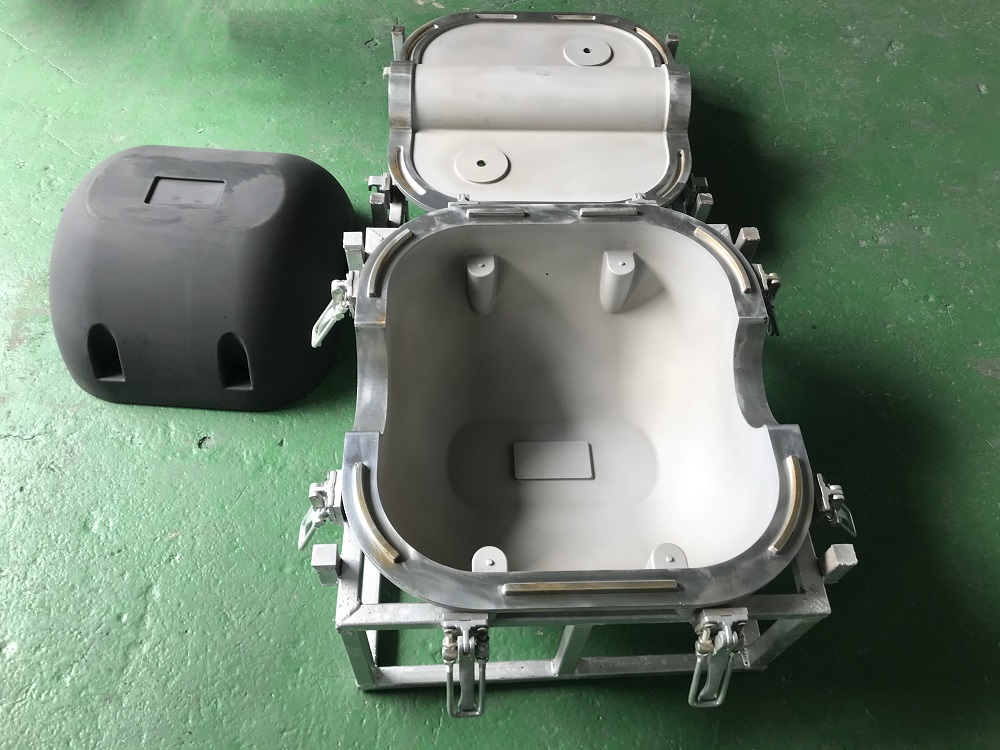

Types of Rotational Molds

We offer various types of rotational mold tooling, depending on your specifications and applications. From prototype mold tooling to production and export molds, Fly Plastic is your reliable partner.

Our Rotational Molding Processes

See how we process your orders, from quotation to tooling, as our machines and efficient team ensure you receive your molds and parts within the scheduled lead time.

Request your quote from upload your drawings and our dedicated engineers will provide a response within 24 hours, ensuring the process goes on smoothly.

DFM Report

To ensure we can produce functional molds, we offer feasibility reviews of your design to ensure we can fulfill requirements before starting production.

Mold Flow Analysis

Predictive modeling software helps us look at the way molten material moves and acts within the mold, which helps us deliver improvements.

Tooling Production

Using your preferred materials enables us to make mold tooling that is of high quality and can readily fit your applications.

1st Sample Inspection

1st sampling will be delivered for you to review prior to manufacturing plastic parts to ensure precision and quality.

Low Volume Production

After the trial production phase, we begin batch production, which uses powerful machining to manufacture parts at fast rates to save on time and costs.

Strict Inspection

We follow international tolerance standards to ensure our parts meet your parameters.

Delivery

As our team handles packaging to secure our parts neatly for transport, we partner with logistics companies to schedule a timely delivery to your region.

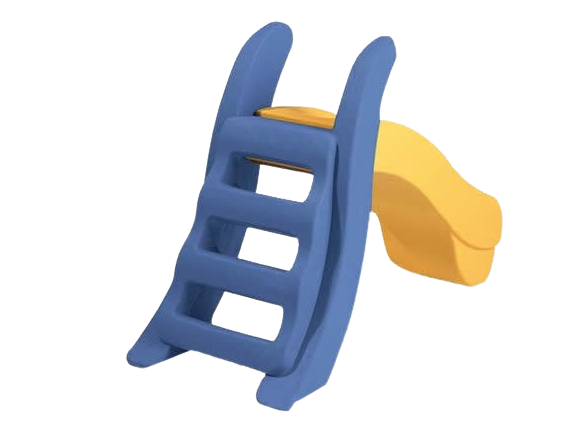

Gallery of Rotational Molding Parts

Dive into FLY Plastic’s extensive gallery that showcases some of our completed rotational molded parts and take confidence that we can create your rotational molding project according to your strict specifications.

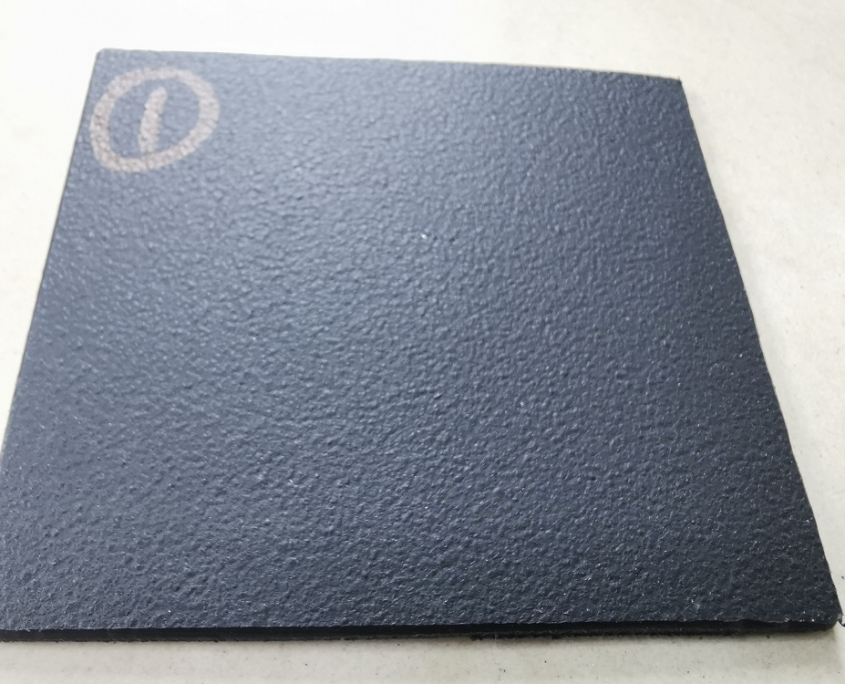

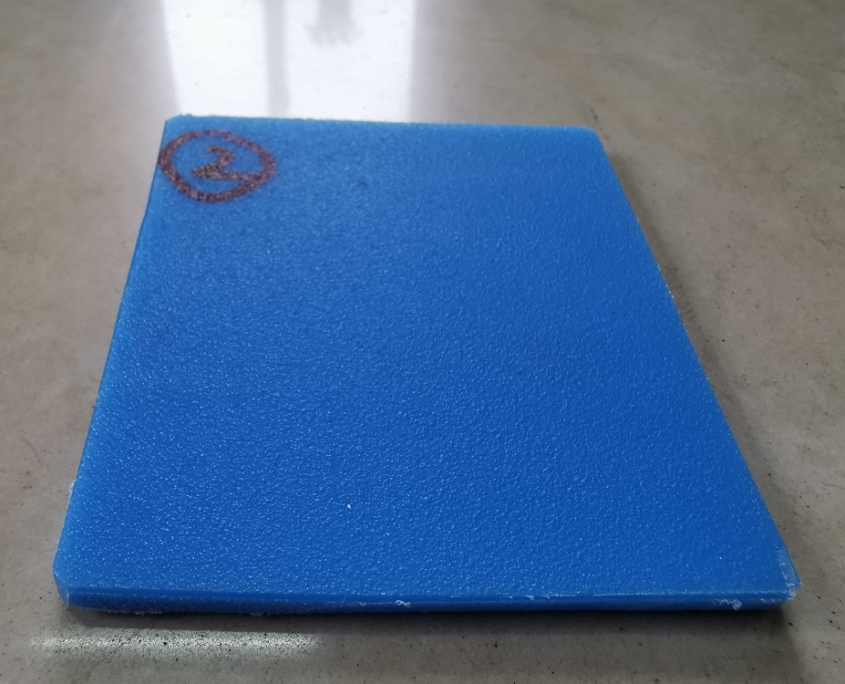

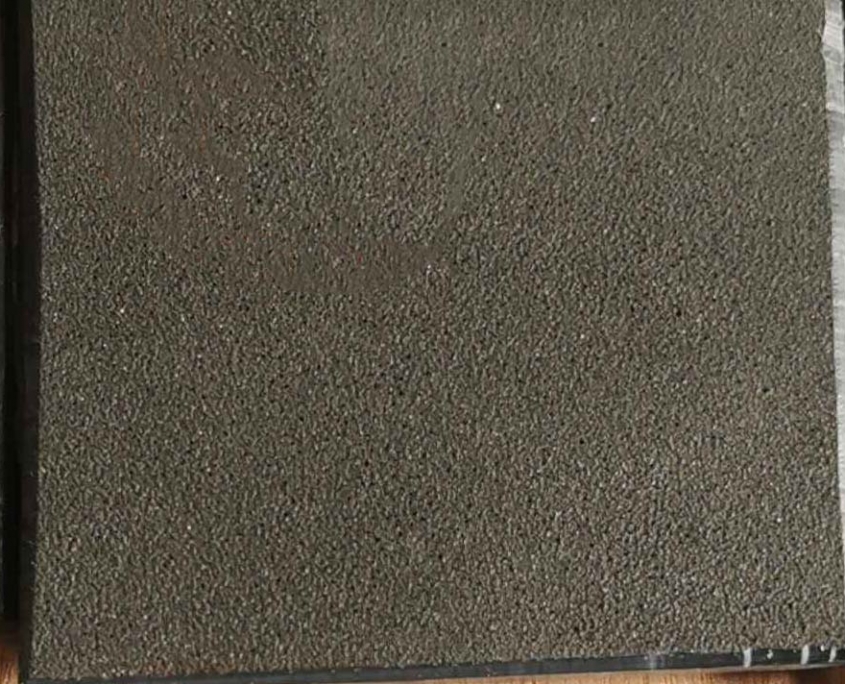

Surface Finishes of Rotational Molding

The surface treatment of the roto mold is usually completed before the production process. After the rotational molding tool is completed, we will implement certain surface treatments on the finished product as per your requirement.

Why Choose Fly Plastic For Custom Rotational Molding Service

No MOQ

No minimum order requirement helps move plastic molded parts from design to production in a fast turnaround and supports your on-demand molding manufacturing needs with reduced rotational molding cost.

High Efficiency

With certified domestic factories and a strong supply chain system, we accelerate the product development cycle and bridge the production of your rotomolded parts as fast as possible.

Consistency and High Quality

Owing certified factories, conducting in-process inspections and dimensional verification after production, guarantee the custom molded parts are consistent in quality regardless of the complex shape with high precision.

Rotational Molding Specialists

Working with our experts having 10+ years of experience in the rotational molding industry, efficiently complete a turnaround from prototyping to production.

See What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

Ready to Get Your Custom Rotational Molding Quotes?

Learn what you need before requesting for quotes for your rotational molding projects at Fly Plastic. Help you get wonderful molded parts made effectively, easily.

Our Rotational Molding for Various Industrial Applications

Fly Plastic works with leading manufacturers from different industries to support growing demands and streamline their supply chain. The digitalization of our custom injection molding services helps more and more manufacturers bring their idea to products.

Traffic

Spa

Playground

Military

Outdoor Sport

Flower Pot

Let's Start A New Project Today

Frequently Asked Questions

Once we get the 3-D drawings (detail information) from you,we will check your drawings carefully.Then we will provide our quotation for your molds. If everything is fine and you confirm to place order to us,we will ?send the invoice to you.

Normally we accept 50% T/T in advance and the balance payment after you confirm our sample is qualified.We will arrange the shipment after we receive your balance payment.

1. Generally we will delivery samples by express such as Fedex,DHL,TNT,etc.

2. The molds will be shipped by sea or air according to your requirements

3. The rotational molding products will be shipped by sea.

1. Molds depends on the quantity and complexity of the molds.Generally 30-40 days.

2. Rotational molding products depends on the quantity and forming time.15-30 days.

To check this question, I think you have received our invoice and noted our invoice bank account name is not Fly Plastic.

Fly Plastic is a son brand.

Our company legal name is Ningbo Roto Plastic Co., Ltd., But we usually use our agent account to receive the order funds.

At present, we use two agent bank account:

Bank account name: Ningbo Shinsh Import and Export Co., Ltd.

Account Number:3901110009814051342

Bank account name: Ningbo Haishu Running Environmental Scl-tech Co., Ltd.

Account Number:40062025000008469

If you also have some worries, we also can make the invoice by Ningbo Roto Plastic Co., Ltd, but the offer needs to be improved 10%.

Bank account name: Ningbo Roto Plastic Co., Ltd.

Account Number: 3901340009814027922